The milling industry

Bindewald, Cornexo, Plange, Rettenmeier mill, Rheintal mills, Saale + Dresden mills, biomill by VogtlandBioMühlen – all names that sound good, all names replete with history and tradition which, as one-time purely artisanal mills and trading houses, made the leap from the agrarian age into the digital age with style. Bound together in a powerful strategic alliance, the Bindewald & Gutting Milling Group came together with the stated objective of improving our foodstuffs and making their manufacture more efficient and safer.

What remains is not only the embodiment of the mill but also many reputable occupations which have reinvented themselves over the years. They have become much more technically complex but not less significant in their reputation as they are indispensable for the manufacture of high quality foodstuffs and will therefore remain essential in the future.

Anyone entitled to call themselves a miller, or in today’s language a “process technologist in the milling and grain industry (m/f/t)” bears this job title with pride.

Facts and figures about our industry and Group:

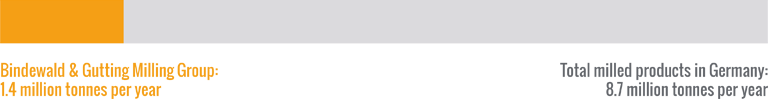

German mills grind about 8.7 million tonnes of grain every year. Bread-making varieties such as wheat and rye make up as much as 8.3 million tonnes of this. Of these, about 7.5 million tonnes are soft wheats and 800,000 tonnes are rye. Approximately 400,000 tonnes of durum wheats are also ground.

This produces about 6.1 million tonnes of wheat flour, 700,000 tonnes of rye flour and 305,000 tonnes of milled products made from durum wheats.

Total milled wheat, rye and durum wheat products in Germany

Quality Assurance, guaranteed safety

One of the core preoccupations of our milling operations is continuous quality enhancement and the optimisation of all aspects of product safety. Our internal company standards are far more strict than legal requirements. Working in conjunction with the Association of Grain, Milling and Starch Industries (Verband der Getreide-, Mühlen- und Stärkewirtschaft) we are always at the forefront with regard to foodstuffs legislation, Quality Assurance, hygiene and storage protection.

Controlled processes for secure outcomes

We ensure that the end product exhibits the desired properties during each individual processing step. To achieve this we have refined our processes down to the very last detail. Every process is permanently monitored on-line and the process parameters controlled accordingly.

At any point in time we know precisely how our product in production is coming along. Our final inspection is in fact a validation of our production process.

This attention to detail extends to the transportation of our products for which we have our own truck fleet and cleaning facilities for our silo trucks so that our products arrive safely and unadulterated at our customers. Thus it is of the greatest possible importance for our milling companies to organise themselves strategically and sustainably, and to detect changes in the bread and bakery products markets at an early stage.

Development of training and countering the skills shortage

In our milling group, specialist trades are more multifaceted than ever before: our specialist areas of grain technology, food technology, application technology, milling technology, logistics and the associated commercial processes demonstrate the wide range of requirements and jobs. The principle still applies today: a mill is only as good as the people who work in it.

Our milling operations highlight the outstanding prospects for our staff. The career opportunities are considerable, the chances of being recruited after training are very high and the opportunities for further training are virtually limitless. How far can further education and training go with us? As the first and until now only mill in Germany we employ a person who is allowed to call himself a “bread sommelier”.

The wide range of specialisations turn our mills into production sites, but at the same time they are also technology centres for grain technology, food technology, application technology and milling technology. The associated logistics and all the commercial processes are also at the highest level. As we manufacture a basic foodstuff in our mills, we are almost totally unaffected by the fluctuations of the economic cycle. This also safeguards jobs and creates opportunities.

We promote the mills of our country

Enthusiasm for the subject is the essential ingredient for awakening enthusiasm in people for milling, the milling industry and for our products. We promote the variety of our profession, the importance of our industry for the bread, beer and foodstuffs of Germany, and in our own interest of course, particularly the people who work for us and earn their living through us.